Polypropylene (PP) is one of the most widely used thermoplastic polymers across various industries. At Swami Polymers, we work extensively with PP because it offers an exceptional balance of strength, durability, and cost-effectiveness. In this guide, we explain what PP is, how it’s manufactured, and why it is a preferred choice for countless industrial applications.

What Is Polypropylene (PP)?

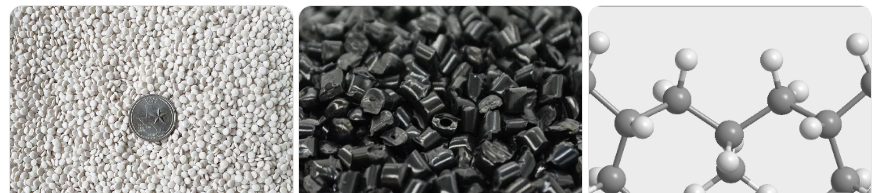

Polypropylene is a versatile thermoplastic polymer made from propylene (propene) monomers. Its chemical structure consists of repeating units of CH₂–CH(CH₃), giving it a unique balance of strength and flexibility.

Key Characteristics of Polypropylene

-

- Lightweight yet strong

-

- High chemical resistance to acids, alkalis, and solvents

-

- High melting point (160–170°C) suitable for hot-fill applications

-

- Excellent fatigue resistance (ideal for living hinges)

-

- Customizable — can be rigid or flexible depending on processing

-

- Recyclable (Plastic Code #5)

Because of these advantages, PP continues to be one of the fastest-growing thermoplastics worldwide.

How Polypropylene (PP) Is Made

The production of polypropylene involves a detailed polymerization process that transforms propylene gas into solid plastic granules. Let’s break it down step by step.

1. Raw Material Preparation

Propylene gas (C₃H₆) is primarily obtained from:

-

- Crude oil refining

-

- Natural gas processing

Before polymerization, the gas is thoroughly purified to remove contaminants that could interfere with catalyst performance.

2. Polymerization Process (Ziegler–Natta Method)

The most common manufacturing technique is Ziegler–Natta catalytic polymerization, which delivers high-quality PP with consistent molecular structure.

During this process:

-

- Propylene monomers enter a controlled reactor.

-

- A titanium-based Ziegler–Natta catalyst is introduced.

-

- Under moderate temperature (60–80°C) and pressure, the catalyst enables monomers to form long polymer chains.

-

- As a result, the polypropylene polymer begins to form.

This method is widely used because it allows precise control over:

-

- Molecular weight

-

- Degree of crystallinity

-

- Isotacticity (which affects strength and clarity)

3. Processing into Pellets

Once polymerization is complete:

-

- The polymer is separated from the catalyst

-

- It is washed, dried, and cut into plastic pellets

-

- These pellets become the raw material for manufacturing PP products through:

-

- Injection molding

-

- Extrusion

-

- Blow molding

-

- Thermoforming

-

- These pellets become the raw material for manufacturing PP products through:

Types of Polypropylene

1. Homopolymer PP

-

- Strong

-

- High melting point

-

- Commonly used in packaging, textiles, and rigid applications

2. Copolymer PP (Random & Block)

-

- Improved impact strength

-

- Better performance at low temperatures

-

- Used in automotive components, pipes, and medical products

Common Applications of Polypropylene

Polypropylene’s balance of performance and affordability makes it suitable for a wide variety of applications. At Swami Polymers, we supply PP for industries such as:

Packaging Industry

-

- Food containers

-

- Bottle caps

-

- Film & sheets

-

- Household storage products

Automotive Sector

-

- Battery cases

-

- Interior components

-

- Bumpers & trims

Textile & Fiber Industry

-

- Non-woven fabrics

-

- Carpets and rugs

-

- Geotextiles

Medical & Laboratory Products

-

- Syringes

-

- Medical trays

-

- Labware

Industrial Uses

-

- Pipes

-

- Chemical tanks

-

- Electrical components

Why PP Is a Preferred Choice at Swami Polymers

At Swami Polymers, we choose polypropylene for manufacturing and supply because:

-

- It offers excellent durability and resists environmental stress.

-

- It maintains shape and strength at higher temperatures.

-

- It provides cost savings compared to many engineering plastics.

-

- It ensures long-term reliability in diverse applications.