Polyvinyl Chloride (PVC) is one of the most important and versatile synthetic plastic polymers used worldwide. At Swami Polymers, we supply high-quality PVC materials that support industries such as construction, electrical, packaging, and medical manufacturing. Because of its exceptional durability, chemical resistance, and cost-effectiveness, PVC continues to be a top choice for engineers, manufacturers, and product designers.

What Is PVC (Polyvinyl Chloride)?

PVC is a thermoplastic polymer made by polymerizing vinyl chloride monomers (VCM). Due to its adaptable structure, PVC can be formulated to be rigid, semi-rigid, or flexible, making it suitable for hundreds of industrial and commercial applications.

Key Characteristics of PVC

- Excellent chemical resistance

- High durability and long service life

- Flame-retardant (self-extinguishing)

- Good electrical insulation properties

- Cost-effective and easy to process

- Can be rigid (uPVC) or flexible (Soft PVC)

- Weather and abrasion resistance

Because of these properties, PVC is one of the most widely used synthetic materials in the world, especially in construction and piping industries.

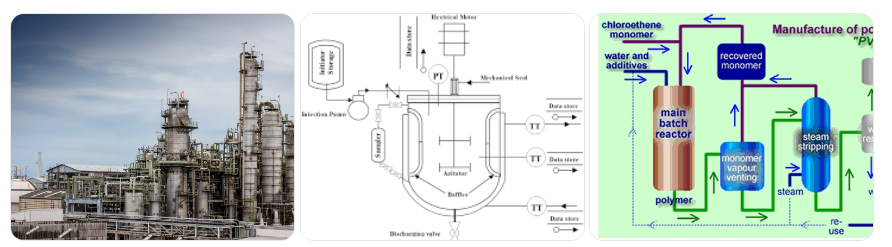

How PVC Is Made

PVC production involves converting vinyl chloride monomers into a solid polymer through controlled polymerization.

1. Raw Material Preparation

PVC starts with ethylene (from crude oil or natural gas) reacting with chlorine to create vinyl chloride monomer (VCM).

Before polymerization, VCM is purified to remove impurities that may affect product quality.

2. Polymerization Process

The most common method is Suspension Polymerization, where:

- VCM is dispersed in water

- Special initiators trigger the polymerization reaction

- Under controlled temperature and pressure, VCM molecules link to form polyvinyl chloride polymer chains

After polymerization:

- The PVC resin is separated from water

- Dried

- Filtered

- Converted into PVC resin powder or granules

This raw PVC resin is the base material used for manufacturing thousands of products.

3. Formulation & Compounding

Pure PVC is rigid by nature.

To create different grades, additives are mixed such as:

- Plasticizers (for flexibility)

- Stabilizers

- Lubricants

- Fillers

- Color pigments

At Swami Polymers, we provide PVC materials tailored to meet specific performance requirements depending on the industry.

Types of PVC

1. Rigid PVC (uPVC)

- Used in pipes, doors, windows, fittings

- Strong and impact-resistant

- Weatherproof and corrosion-resistant

2. Flexible PVC

- Used in cables, hoses, flooring, medical tubes

- Soft, bendable, and lightweight

3. CPVC (Chlorinated PVC)

- Higher heat resistance

- Used for hot water pipes and industrial fluid handling

Applications of PVC Across Industries

PVC’s adaptability makes it one of the most used industrial materials. At Swami Polymers, our PVC materials support industries such as:

Construction & Infrastructure

- Water supply pipes

- Drainage systems

- Window frames

- Doors and profiles

- Roofing sheets

Electrical & Electronics

- Cable insulation

- Conduit pipes

- Connector covers

Packaging

- Shrink films

- Blister packs

- Food-grade wraps

Healthcare & Medical

- IV tubes

- Blood bags

- Medical containers

General Industrial Applications

- Hoses

- Conveyor belts

- Flooring materials

- Synthetic leather

Why PVC Is Preferred by Swami Polymers

At Swami Polymers, we choose PVC because it provides:

- Long lifespan with low maintenance

- Excellent performance in demanding environments

- High recyclability and sustainability potential

- Cost-effective manufacturing options

- Versatility across multiple sectors

Our PVC materials meet industry standards and support both small-scale and large-scale manufacturing needs.